| Brand | EXCELLENT |

| Load Capacity | 2~150t |

| Table Size | can be customized |

| Wheel Base | 1200~2000mm |

| Running Speed | 0~25m/min |

| Battery Voltage | 48V |

| Running Distance | 50~80m |

| Control Mode | button / remote control |

| Certificate | CE, ISO |

| Place of Origin | Henan, China |

Electric rail transfer trolley is a low-voltage track powered electric flatbed powered by sliding contact wires on the track. The track is both the walking track of the wheels and the feed track. It has 36V single-phase power supply and three-phase power supply. The grounding step-down transformer control cabinet steps down single-phase (three-phase) AC 380V to single-phase.

Due to the fact that the walking track is also used as a feed track, insulation is required between the track, wheels, and vehicle body. Special insulation treatment should be carried out during the laying of steel rails.

Model | KN-2t | KN-20t | KN-50t | KN-100t | KN-150t | |

Rated Load(t) | 2 | 20 | 50 | 100 | 150 | |

Table Size(mm) | Length(L) | 2000 | 4000 | 5500 | 6500 | 10000 |

Width(W) | 1500 | 2200 | 2500 | 2800 | 3000 | |

Heigth(H) | 450 | 550 | 650 | 850 | 1200 | |

Wheel Base(mm) | 1200 | 2800 | 4200 | 4900 | 7000 | |

Rail Inner Gauge(mm) | 1200 | 1435 | 1435 | 2000 | 2000 | |

Wheel Diameter(mm) | 270 | 350 | 500 | 600 | 600 | |

Wheel Quantity | 4 | 4 | 4 | 4 | 8 | |

Ground Clearance(mm) | 50 | 50 | 50 | 75 | 75 | |

Running Speed(min) | 0-25 | 0-20 | 0-20 | 0-20 | 0-18 | |

Motor Power(kw) | 0.8 | 2.5 | 5.5 | 11 | 15 | |

Transformer Power(KVA) | 3 | 6.8 | 10 | 30 | 30 | |

Transformer Quanity | 1 | 1 | 1 | 1 | 1 | |

Running Distance(m) | 70 | 70 | 50 | 50 | 50 | |

Max Wheel Load(KN) | 14.4 | 77.7 | 174 | 343.8 | 265.2 | |

Reference Weight(t) | 2.8 | 5.9 | 8 | 14.6 | 26.8 | |

Recommended Rail Model | P15 | P24 | P43 | QU100 | QU100 | |

If you want to get a price of our Rail transfer cart, please help to confirm the details as below:

1. the capacity: ton?

2. the table size: width and length?

3. the power supply way: battery type, electric cable type?

4. the power supply:380v,50HZ, 3 PHASE?

5. which goods the trolle will carry?

6. The qty? CIF price to which port?

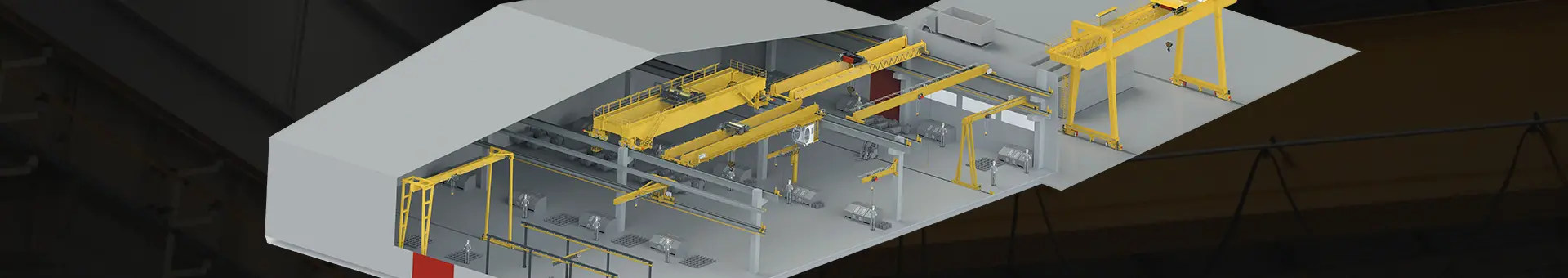

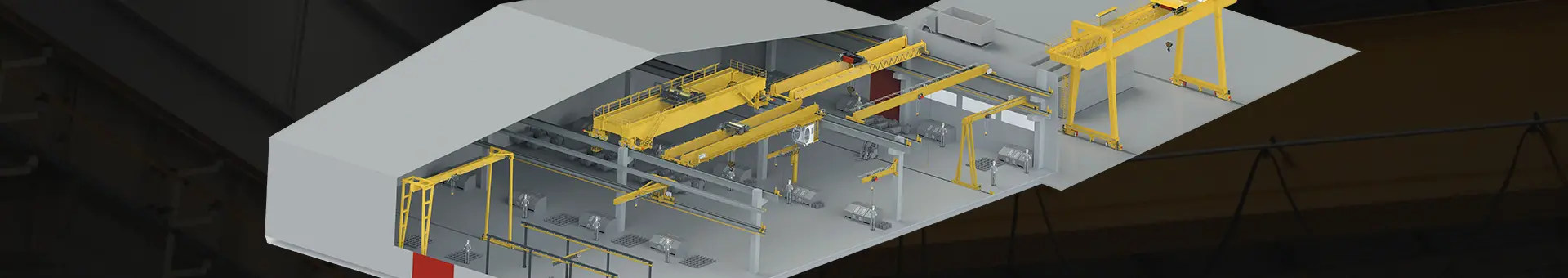

1. Manufacturing & Production Facilities

Used for moving large, heavy components (e.g., machinery, workpieces, and tooling) within production lines.Commonly found in automotive, aerospace, and steel manufacturing plants.Helps in transporting materials from one assembly stage to another, reducing manual labor and improving efficiency.

2. Heavy Industry & Steel Mills

Common in steel plants, foundries, and heavy manufacturing for transporting steel billets, ingots, or molds.Operates in extreme environments like high temperatures and heavy loads.Used to move materials like steel coils, scrap metal, and finished products.

3. Warehousing & Distribution Centers

Efficiently moves goods (e.g., pallets, large boxes, and containers) over long distances within warehouses or large distribution centers.Often integrated into automated systems, transporting products between different storage zones.Supports inventory management by allowing seamless transfer of goods across the facility.

4. Automotive & Shipbuilding

Used in automotive assembly lines and shipbuilding yards to move components (e.g., car chassis, engines, ship hulls).

Can be designed for precise positioning to handle large structures and move them to different workstations.

Helps streamline the assembly or maintenance processes in industries that involve heavy or bulky equipment.

5. Ports & Cargo Handling

Found in port terminals for transporting shipping containers across the dock, loading/unloading goods from ships to warehouses or trucks.Often integrated with overhead cranes or gantry cranes to move heavy items on the dockside.Used in container yards and for bulk material handling in ports.

6. Aerospace Industry

Used for transporting aircraft components (e.g., fuselages, wings, and engines) within assembly or maintenance facilities.Helps in moving parts safely and efficiently across different stages of the production line.

7. Mining & Raw Materials

Used in mining operations to transport mineral ores, tools, and equipment across mines and processing plants.Transfers materials to stockpiles, crushers, or refining units, allowing continuous mining operations.Can be used in underground mining with specialized carts for rugged conditions.

All kinds of Overhead Crane, Gantry Crane, Electric Hoist, Transfer Cart, Industrial Electric Winch, Radial/Flat Gate Hoist, Steel Gate, etc.

Yes, as a Single girder 10 ton overhead crane sale manufacturer, we can offer all the related spare parts. Such as motor, hoists, drums, wheels,grabs, hooks, rails, travel beams, enclosed bus bar, etc.

Specific parameters such as lifting capacity, lifting height, span, cantilever length if have, power supply voltage, control method, etc.

Yes, of course. We are manufacturer and we have our own engineer group. They can work out customized design according to your requirement. The most important thing is that you should tell us what you need.

Before the delivery, every products will be tested. We will constantly check the quality during the manufacturing process, and strictly test the equipment before shipment, and we will also send you a quality certificate for each crane. You are also warmly welcomed to come to our factory for inspection.

Yes, we have a professional installation team and have been to manycountries to assist in installation. lfyou need us to provide this service,pleaselet us know in advance and we will provide you with the best solution.

We have after-sales team to support you for 24hours.

Safest package chosen to protect your goods during transportation.

Alibaba pay、 Alibaba Trade Assurance、T/T、L/C.